The development of technology in our world is gaining mad pace. What is the reason? The main reasons for the development and promotion of our new and totally positive peace. And every day we all Approximations and become one step closer to perfection.

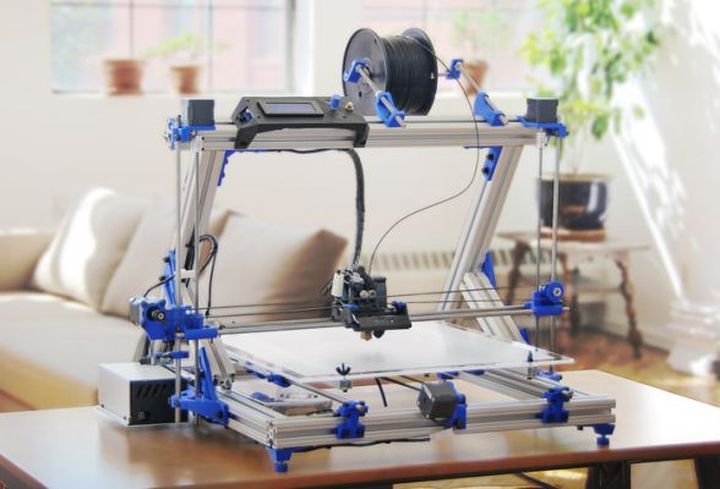

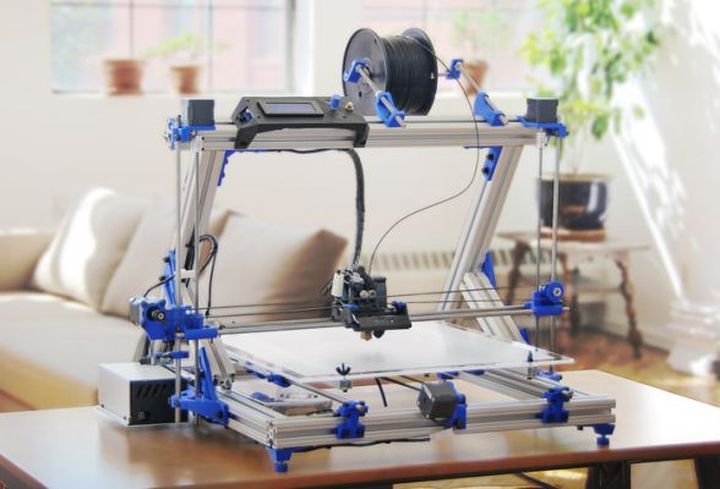

Today would like to talk about 3D printing. Let’s see what advances we have made and what it will lead us.

Many companies manufacturers every day improving and work on 3D printers. To date, a major step in the development of not only 3D printers. But the development of 3D scanning of objects.

A lot of time was spent on the improvement and development of 3D printer and scan objects. And as you can see, all the work done is not in vain. Many objects contribute to the production of those components and mechanisms that will help to improve the production of certain components for small producers directly in their place. This will reduce the delivery time and the time of manufacture of the product itself.

But the main problem of the production facilities was the material of which produces object itself. And this material you know the usual plastic. And this plastic was not suitable for certain parts of our lives. The structure of this plastic is not consistent with the indicators that need a standard. Plastic basically had a very strong and “not” solid structure.

But now the producer of Disney Research moved to a new level of production. And can use a different kind of material for its production of parts. And at the moment of their 3D printer can print materials from soft and durable material structure. This will allow the use of elements of building.

The basic principle of the new 3D printer from Disney Research

The 3D printer that is capable of printing a soft and flexible material has the basic elements. Includes a printhead and a laser knife.

An object produced in two stages: first, the material lays down, basically that the material has a fabric structure. Then the process 2d laser knife burns a certain form laid down by the program. And so we get the desired object to us.

Every day we see new opportunities for our implementation. And technology in our world comes in small steps, but with a gorgeous result.

Source: DisneyResearch

Read another very interesting article about alternative energy of the Sun, water and air.